3500 Psi Polished Floor Cement Content

Free homes for the improvements concrete strength up to 3 500 to the 4 500 psi is enough.

3500 psi polished floor cement content. When making of walls and footings concrete psi strength 2 500 is enough could be between the 4 000 up to 5 000 psi needs for the pavements for construction. Provide consistent finish in all contiguous areas. Concrete mix design for polished concrete. Concrete with psi levels exceeding 3 500 is used for construction of foundations and floor slabs.

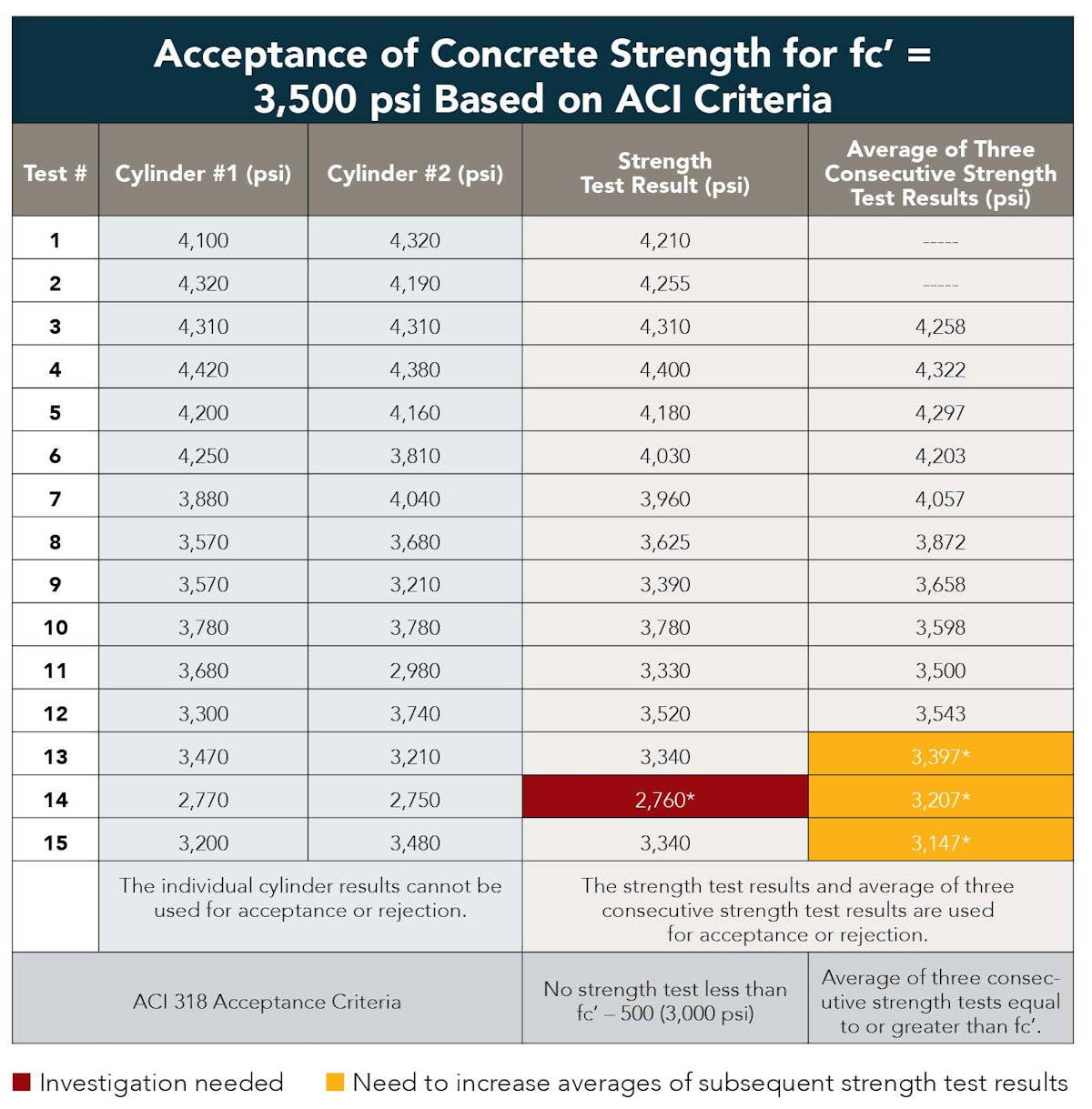

Verify concrete is cured to 28 day duration and 3500 psi 24 mpa strength. 3 500 psi to 5 000 psi. Provide polished concrete floor treatment in entirety of slab indicated by drawings. Part of the cpc s mission is to establish a clear concise technical foundation for the concrete polishing industry.

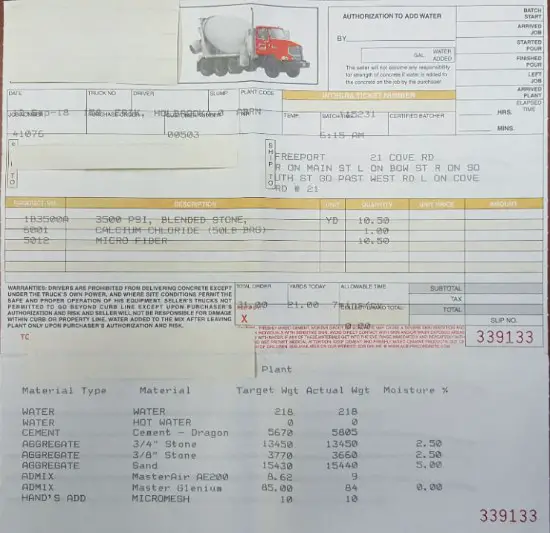

Use a minimum 3 500 psi mix. Between 3 500 and 5 000 is preferred for polished concrete. I ll show you the actual concrete batch plant ticket with the cement sand and aggregate break downs for the yards we used. Many states prohibit the use of concrete for construction with psi levels under 2 500.

I also researched my ass off on what concrete specs mean and how they concoct the stuff. Place concrete to achieve as true and smooth a top surface as possible. This type of concrete can be used while damp. 3 000 psi is normal for concrete driveways concrete sidewalks and patios.

I had a long talk with the plant super mix plant is 2 blocks away and decided to go with 3500 mix with the same large rock. Suspended slabs beams and girders as often found in bridges require 3 500 to 5 000 psi. Verify concrete surfaces have received a hard steel trowel finish 3 passes during placement. Minimize driver added water maintaining a 45 water content ratio.

The cpc has worked closely with polishing contractors manufacturers and designers to compile specifications guidelines and position statements. For the need of non reinforce concrete uses in different types of strengths are required for the structure. Not allowed if aggregate. You can do this.

Harris explains that in order to be successful with this application he gypsum must have a psi of 3500 psi at a minimum. These are the actual concrete mix ratios for 3000 3500 4000 and 4500 psi concrete that i use to pour concrete floors patios pool decks and more. Concrete footings and slabs on grade typically require a concrete of 3 500 to 4 000 psi. For my needs the slow cure low psi mix sounded like just the ticket and i don t regret it.

1 02 work in the section applies to polishing concrete floor surfaces to a. This type of flooring option is helpful in apartments and condominiums because it helps absorb sound. If you feel the need to have air entrained concrete try not to exceed 3. Harris first sands the floor in preparation of applying two coats of duraamen cp1000 primer.